Innovation in crushing and screening that enables quarries to engineer a resilient supply of sand for construction.

How will you make yours?

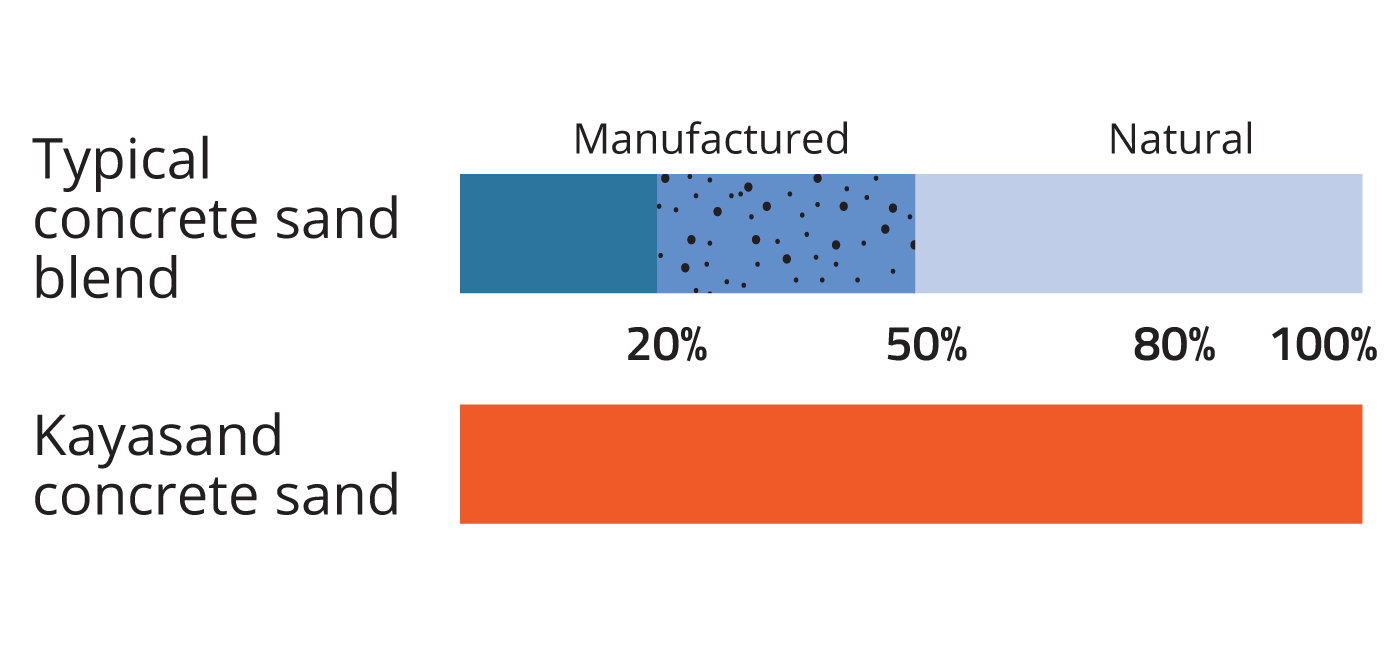

Transform crusher dust into premium products and extract utrafine byproducts during processing.

Eliminate crusher dust stockpiles, large scale water treatment facilities and ultrafine disposal.

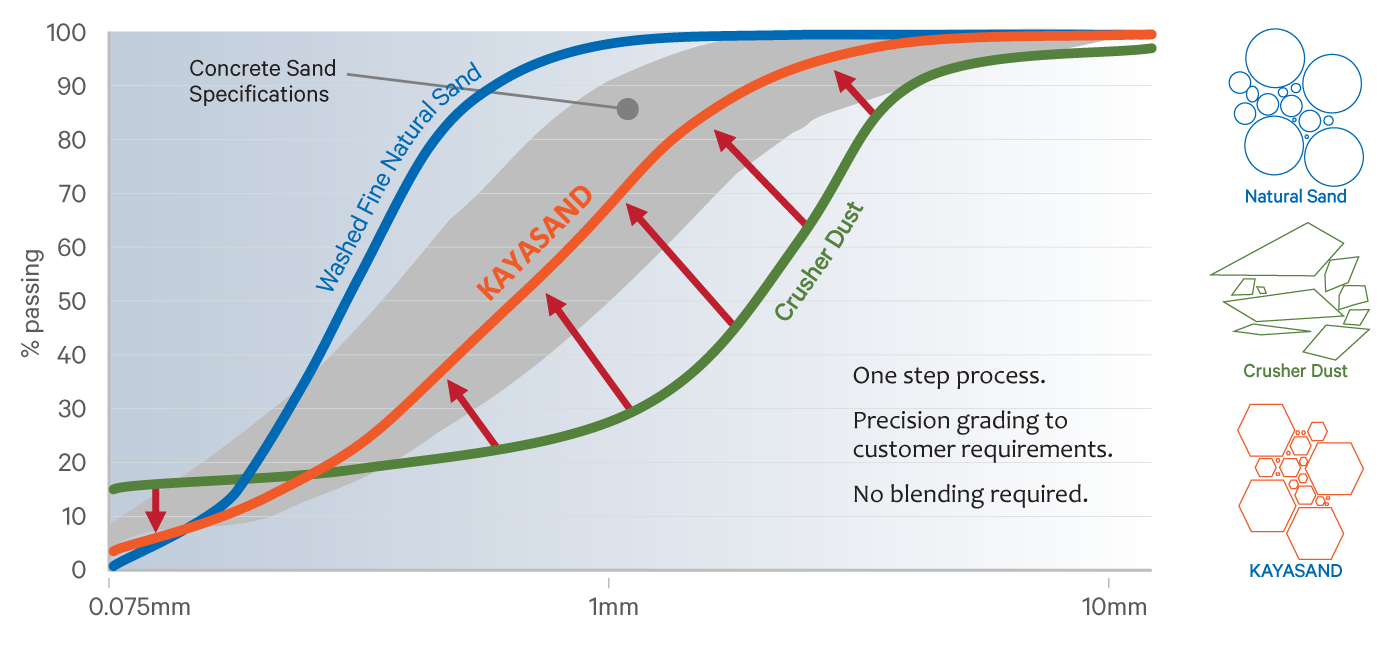

Easy adjustment of product gradings and ultrafine (<75μm) levels to precisely and consistently meet customer specifications.

Process a wider range of materials, extract contaminants, shape particles and make a precisely graded product every time.

Crusher dust. Particles all passing.

Recycled glass. Recycled concrete. Slag.

Fully enclosed and operating under negative pressure means no dust.

No need for ponds to treat wastewater and no sludge to landfill.

Suitable for urban areas where noise must be suppressed.

Advanced sensors and a custom control system mean autonomous operation.

Vertical design takes up less space.

Long life and low wear parts combined with lower byproduct handling costs.

High throughput, precision screening of coarse and fine aggregates

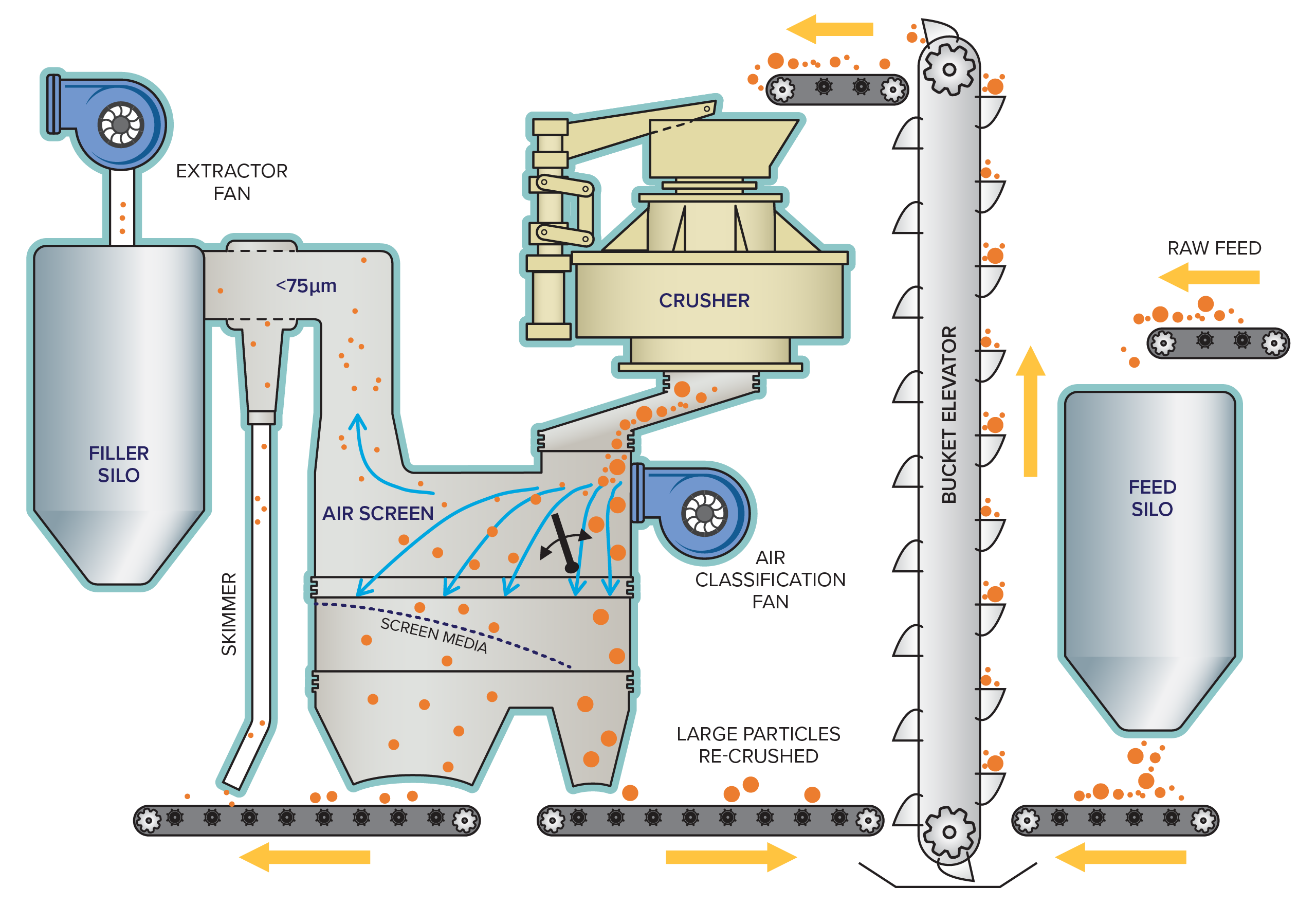

How our V7 engineered sand plants work.

The crusher’s grinding impact action mimics natural erosion to create a cuboidal particle that is ideally shaped for strength and workability in concrete.

The combination of high accuracy screens with high throughput air classification ensures product is made to specification every time.

Water and skimmer material is blended into the final product to meet customer specifications, maximise concrete performance and to supress dust on the stockpile.

Ultrafines are extracted and stored dry until they are needed to dose other quarry products or loaded out into trucks or tankers.

Engineer sand with a cuboidal shape to maximise the pumpability, workability and finishing characteristics of concrete.

Produce the right amount of each particle size to maximise the packing density in concrete, saving on cement and creating a nice creamy finish.

Extract clays, silts and other deleterious contamination to reduce concrete water demand and avoid the need to blend with other sands.

Repeatedly produce the same quality sand, regardless of feed changes, for consistent concrete performance.

| Plant specifications | V7-40 | V7-60 | V7-120 | V7-240 |

|---|---|---|---|---|

| Processing capacity (TPH) | 40 | 60 | 120 | 240 |

| Power usage (kW normal) | 290 | 380 | 760 | 1520 |

| Power usage (kW peak) | 450 | 550 | 1000 | 1900 |

AU/NZ standards compliant for structural, mechanical and electrical design.

Australian Mines Department compliant.

Monitoring. Measuring. Adapting. Autonomous.

“Kayasand's V7-60 technology is cutting edge as far as improving shaping in a sand product. The plant has been instrumental in us [Holcim] getting a significant portion of our manufactured sand into the Sydney market."

Darren Essex, Quarry Manager

Holcim Albion Park

Quarry Magazine, July 2022

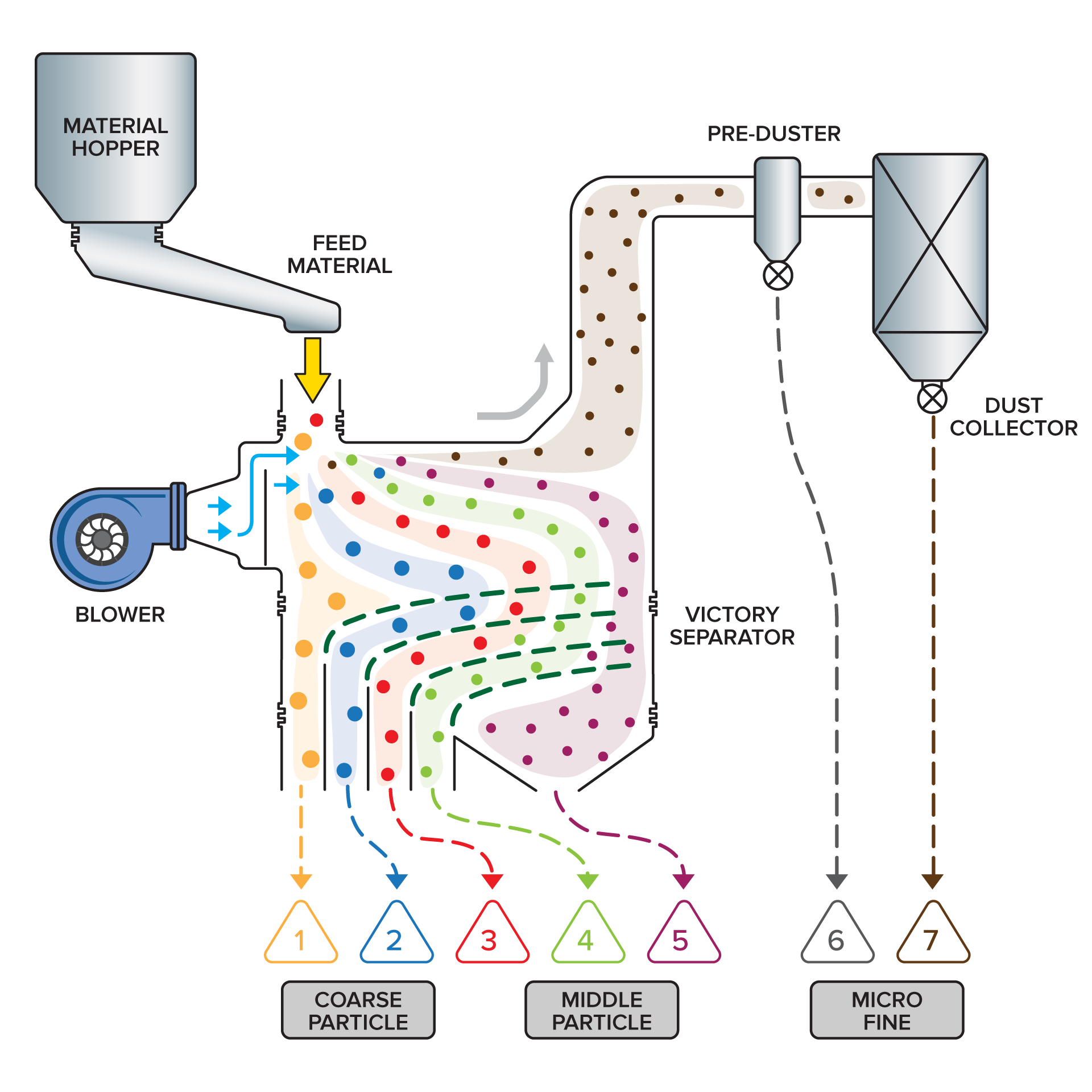

Quad-deck air screens product accurately and consistently every time. Their unique design is the best of both worlds by combining the high accuracy of vibrating screens with the high throughput of air classification systems.

Uses no water for removing ultrafines, ideal for de-dusting coarse aggregates and manufactured sand for use in concrete and asphalt.

Ultrafines are extracted and stored dry until they are needed to dose other quarry products or loaded out into trucks or tankers.

Ultrafine levels in finished product are precisely controlled with a high degree of accuracy down to 0.075mm.

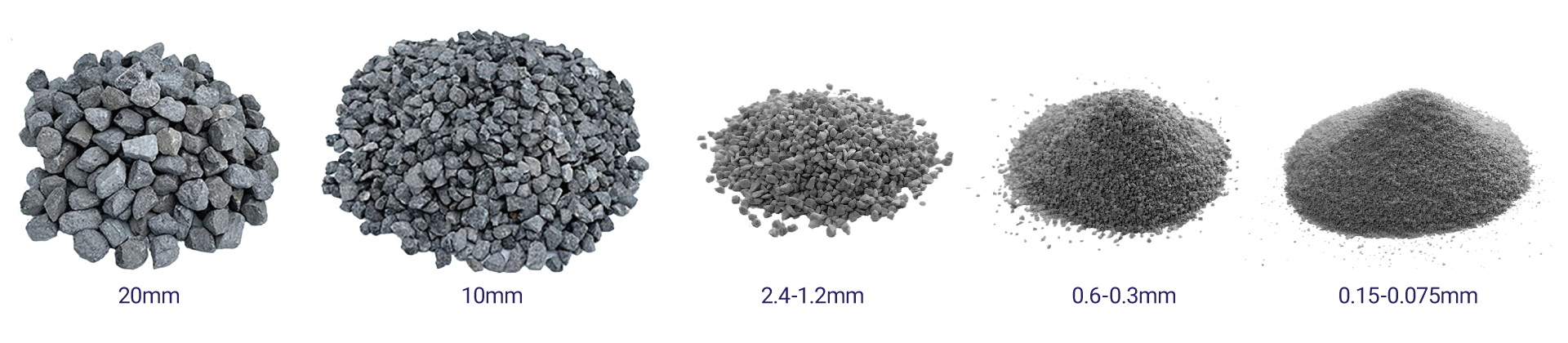

Different mesh sizes enable you to extract and process up to 7 different product fractions simultaneously, ranging from 40mm to <0.075mm.

2x – 10x the processing rate of conventional screens, especially in products with high ultrafines that cause conventional screens to blind over.

| RCAS Specifications | RCAS 900 | RCAS 1200 | RCAS 1900 | RCAS 2500 |

|---|---|---|---|---|

| Power (kw) | 40 | 55 | 65 | 95 |

| Capacity (tph) | 90 | 120 | 190 | 250 |

| Height (m) | 4.5 | 4.8 | 5.0 | 5.4 |

| Width (m) | 1.1 | 1.4 | 1.8 | 2.7 |

AU/NZ standards compliant for structural, mechanical and electrical design.

Australian Mines Department compliant.